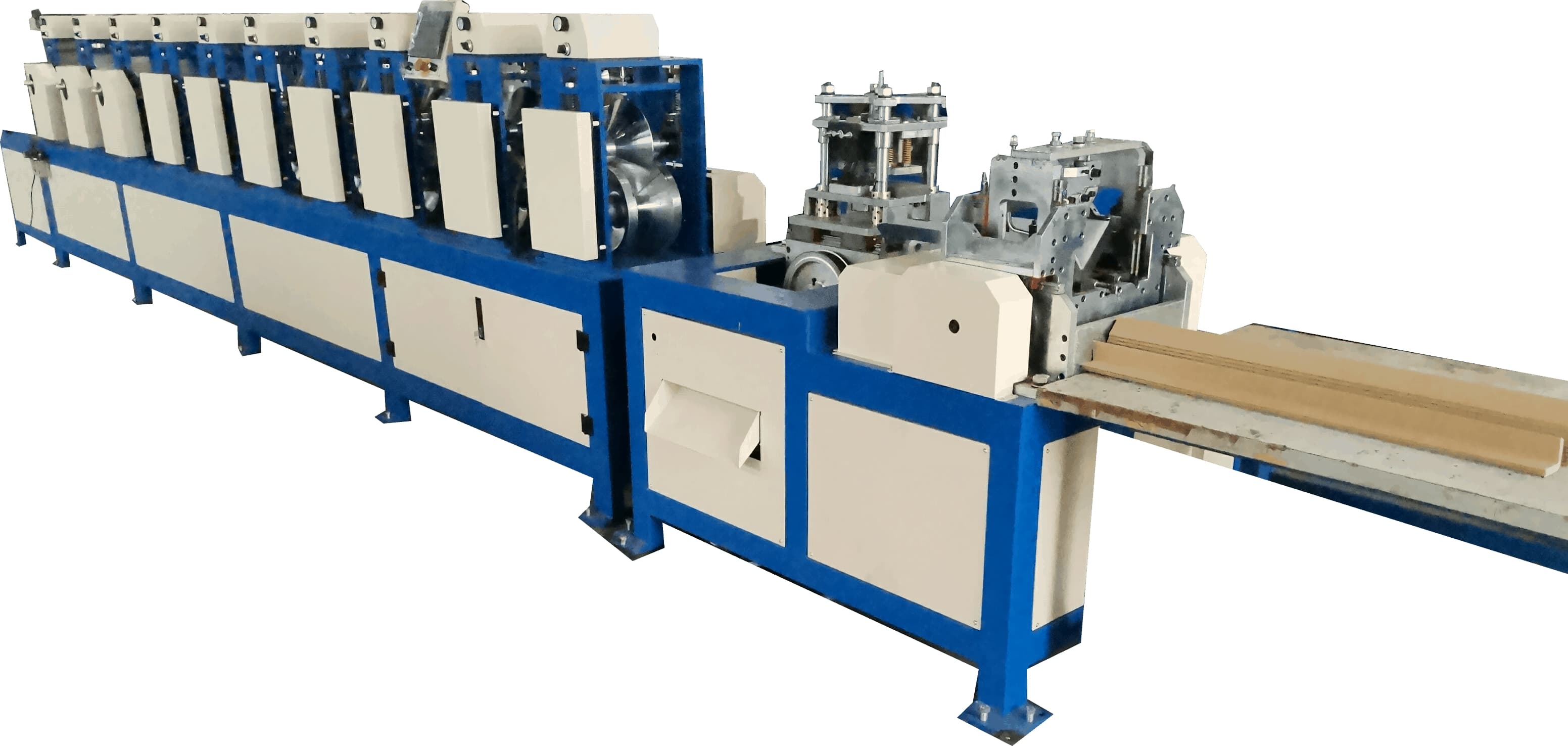

ZJK120DK paper edge protector production line

1.It drives by one axle. All drives parts are thermal refined and surface hardened.

2.It could choose hydraulic cutter or mechanical cutter.

3.It adjusts the pressure by double air cylinders.

4.It is convenient to control the machine with touch screen and servo system. The cut off precision is 1000±1mm.

5.It could see the output on the touch screen.

Contact Us

2.It could choose hydraulic cutter or mechanical cutter.

3.It adjusts the pressure by double air cylinders.

4.It is convenient to control the machine with touch screen and servo system. The cut off precision is 1000±1mm.

5.It could see the output on the touch screen.

- Function Introduction

- Main Technical Parameter

- Application

- Packing and Storage

1.It drives by one axle. All drives parts are thermal refined and surface hardened.

2.It could choose hydraulic cutter or mechanical cutter.

3.It adjusts the pressure by double air cylinders.

4.It is convenient to control the machine with touch screen and servo system. The cut off precision is 1000±1mm.

5.It could see the output on the touch screen.

2.It could choose hydraulic cutter or mechanical cutter.

3.It adjusts the pressure by double air cylinders.

4.It is convenient to control the machine with touch screen and servo system. The cut off precision is 1000±1mm.

5.It could see the output on the touch screen.

| Size of edge board | 25~110mm |

| Thickness of edge board | 2.5~10mm |

| Speed | 60m/min,Economic speed:30~50m/min |

| Size of punching edge board | 40~90 mm According to the punching die |

| Speed of punch | 0~30m/min, (thickness )2.5-5 mm |

| Cut off precision | 1000±1mm |

| Max. layers | 13(layers) |

| GSM of paper |

surface paper175~250gsm(kraft paper) inner paper 420~600gsm(bobbin paper) |

| Total power | 9.5KW |

| The number of press wheels | 5(groups)~10(groups) |

| Dimension | 25000×1350×1700mm |

| Total weight | 4000KG |

English

English 简体中文

简体中文