PBK1600~PBK2000 Honeycomb Board Production line

1.It is convenient for workers to load the paper by hydraulic paper stand or mechanical paper stand. It could reduce the work intensity.

2.Glue system: Customer could choose one type between core gluing or surface paper gluing.

3.Glue system: Gluing by pneumatic way. It makes the glue homogeneous.

4.Cutter: with servo system. High cutting precision.

5.Touch screen: It is convenient for workers to operate the machine by touch screen.

Contact Us

2.Glue system: Customer could choose one type between core gluing or surface paper gluing.

3.Glue system: Gluing by pneumatic way. It makes the glue homogeneous.

4.Cutter: with servo system. High cutting precision.

5.Touch screen: It is convenient for workers to operate the machine by touch screen.

- Function Introduction

- Main Technical Parameters

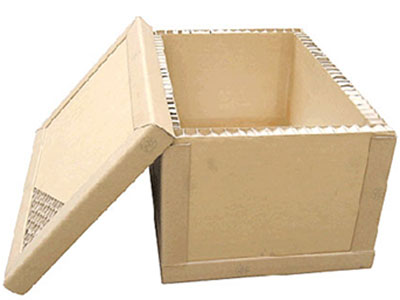

- Application

- Packing and Storage

1.It is convenient for workers to load the paper by hydraulic paper stand or mechanical paper stand. It could reduce the work intensity.

2.Glue system: Customer could choose one type between core gluing or surface paper gluing.

3.Glue system: Gluing by pneumatic way. It makes the glue homogeneous.

4.Cutter: with servo system. High cutting precision.

5.Touch screen: It is convenient for workers to operate the machine by touch screen.

2.Glue system: Customer could choose one type between core gluing or surface paper gluing.

3.Glue system: Gluing by pneumatic way. It makes the glue homogeneous.

4.Cutter: with servo system. High cutting precision.

5.Touch screen: It is convenient for workers to operate the machine by touch screen.

| Max.width of core | 2000mm~2600mm |

| Max.width of surface paper | 1600mm~2000mm |

| Max.width of board | 1600mm~2000mm |

| Thickness of board | 5~100mm |

| Speed | 0~30m/min |

| Min.cutting length | 100mm |

| Cut off precision | 1000±0.2 |

| Heating method | electrical heating、steam heating、oil heating |

| Total power | 130KW-180KW |

| Dimension | (32000~45000)×3300×2500mm |

| Total weight | 35000KG |

English

English 简体中文

简体中文